Products

Cast Resin Dry Type Excitation Transformer voltage class is from 10kV, 13.8kV, 15.75kV, 20kV, 22kV. It usually can be taken single or three-phase, separated HV incoming enclosed busbar, shield equipped between HV winding and LV winding and widely to static excitation system of the hydropower plant and thermal power plant.

1.Phase: 3 phases

2.Rated power: 1250kVA

3.Primary voltage: 10kV

4.Secondary voltage: 0.4kV

5.Frequency: 50Hz/60Hz

6.Vector group: Dyn11

7.Insulation class: H/F Class

8.Application: Excitation system

1.Self-extinguishing and flameproof, no blast, no pollution, non-poison air

2.High moisture resistance, safe operation under 100% humidity, and other bad service environments

3.Strong resin structure without any cracks, good heat dissipation performance.

4.High over-load capacity, it can run at 110% rated load and 150% rated load under AF.

5.Compact size, low cost for installation, and commission.

Technical characteristics for 1250kVA 10kV cast resin dry type transformer

| Transformer type | Cast resin dry type transformer |

| Transformer Model | 1250kVA 10/0.4kV |

| Short circuit impedance | 6% |

| Noise Level | 50dB |

| Cooling mode | AN/AF |

| Winding material | Copper/Aluminum |

| Degree of protection | IP00 |

| HV tapping | +/-2*2.5% |

| Insulation material | Cast resin (HV) Pre-impregnated (LV) |

| Insulation level | Primary: 28kV AC Secondary: 3kV AC |

| BIL | 75kV for primary circuit |

| Type of installation | Indoor |

| Maximum attitude | <1000m |

| Standards | IEC60076-11 |

Application: Static excitation system of the hydropower plant and thermal power plant

After-sales Service: We have a professional aftersales engineer team, each aftersales engineer has more than 3 years of experience. And we also have localized technical backup to offer timely support in Malaysia, South Africa, Egypt, Dubai, UAE, Brazil.

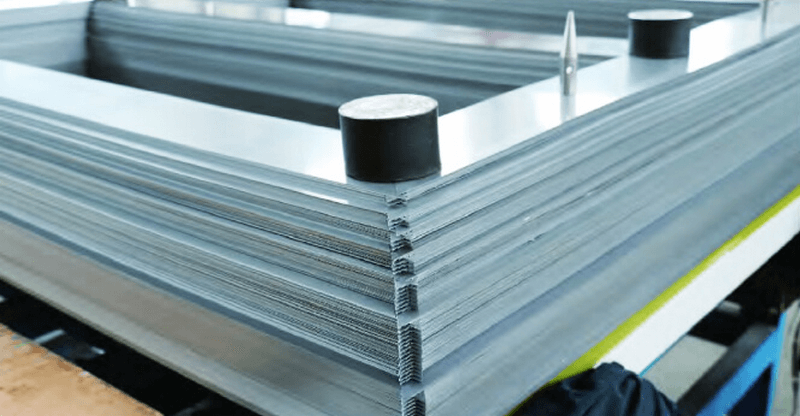

Core:

The core is constructed from cold-rolled, grain-oriented low loss silicon steel lamination which is insulated with the oxide layer. Using 45° stepping all-leaning lamination way to laminate. So the no-load current is reduced efficiently.

The yokes and legs are free of a fixed bolt or butt-jointing penetrating the lamination.

Windings:

The materials of both HV and LV windings are made of high conductivity copper. Both windings are short-circuited proof and are achieved by the type of windings itself and not by the rigidity of the clamp. Copper foil material shall be used as LV windings.

IP protective enclosure:

The standard transformers produced by our company are without the case and their protection level is IP20. We can also provide IP30 or IP40 if you require. The case can be made by common steel plates, stainless steel plants, or aluminum alloy and can be acid-washed,parkerised, and powder-painted.

Temperature controller:

The temperature control displays are installed on the low voltage side of the case, which is reliable and convenient for users to check.

Airforced fan:

The transformer could be designed for AF (air forced) cooling but to be initially supplied for AN (natural

cooling) cooling. Provisions are made for subsequent installation of or cooling which shall consist of 2 or more crossflow fans arranged on either side of the transformer below the windings.

Installation:

Installation:1.Before equipment installation, please first refer to the following materials carefully: this manual, nameplate and overall dimensional drawings, thus to get familiar with the product’s total weight and installation methods and prepare corresponding lifting facility and special tools.

2.The transformer should be kept at least 300mm away from walls, and other equipment during installation. Transformers installed side by side should have at least 300mm clearance.

3.The minimum safe distance between conductors and ground should conform to IEC76-3-1 POWER TRANSFORMERS-INSULATION LEVELS AND DIELECTRIC TEST-EXTERNAL CLEARANCES IN AIR.

4.The minimum safe distance between the HV coil and ground is listed as follows:

| HV voltage | £1kV | 6kV | 10kV | 15kV | 20kV | 35kV |

| Net distance (mm) | 40 | 60 | 90 | 120 | 160 | 250 |

5.Usually, the transformer can be placed directly onto the service site and then be put into operation after installation and inspection. If the transformer must be fastened in place for shock-proof purposes or if there are other special requirements, bolts should be embedded into the foundation. The position of the bolts should be in line with the installation holes of the transformer according to outline drawings. To secure the transformer, remove the wheels and bolt the transformer to the foundation.

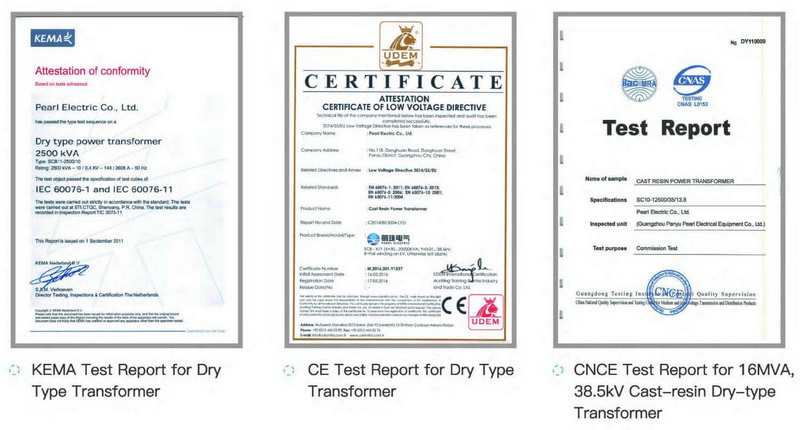

Test capability is an important part to show Pearl Electric’s high quality and R&D results. And each transformer must pass all tests before delivery.

1. Except short-circuit transformer, we can do all routine tests, type tests,s and special tests for our transformer.

2. Having 4 test bays covered Dry-type transformer, oil-immersed power transformer, and transformer substation.

3. Getting a complete set of third-party test certificates for the transformer, included KEMA, CESI, ASTA, CTQC, CNAS.

FAQ:

FAQ:1. Q: Are you a manufacturer?

A: Yes, we are a manufacturer. Our factory is in Guangzhou City, Guangdong Province.

2. Q: Can I get guarantee of products?

A: Yes, every product is 12monts quality warrant under customer correct using the products.

3. Q: Do you have any Certificates?

A: Yes. Each of our units has CE, 3C certificate, and has been awarded by ISO9001/ISO14001. If you need any other

Certificate, we can help you to apply it.

4. Q: How can I pay you?

A: Pay by T/T and L/C is acceptable.

5. Q: What about the production?

A: In general, it takes 4~6weeks and it depends on the different styles.

Copyright © Pearl Electric Co., Ltd.