Products

Cast Resin Dry Type Distribution Transformer is suitable for installation within ventilated enclosure and suitable in every way for operation on the system and under the conditions specified.

1.Phase: 3 phases

2.Rated power: 1000kVA

3.Primary voltage: 11kV

4.Secondary voltage: 0.4kV

5.Frequency: 50Hz

6.Vector group: Dyn11

7.Insulation class: H/F Class

1.Self-extinguishing and flameproof, no blast, no pollution, non-poison air

2.High moisture resistance, safe operation under 100% humidity, and other bad service environments

3.Strong resin structure without any cracks, good heat dissipation performance.

4.High over-load capacity, it can run at 110% rated load and 150% rated load under AF.

5.Compact size, low cost for installation, and commission.

Technical characteristics for 1000kVA 11 kV cast resin dry type transformer

| Transformer type | Cast resin dry type transformer |

| Transformer Model | 1000kVA 11/0.4kV |

| Short circuit impedance | 6% |

| Noise Level | 50dB |

| Cooling mode | AN/AF |

| Winding material | Copper/Aluminum |

| Degree of protection | IP00 |

| HV tapping | +/-2*2.5% |

| Insulation material | Cast resin (HV) Pre-impregnated (LV) |

| Insulation level | Primary: 28kV AC Secondary: 3kV AC |

| BIL | 75kV for primary circuit |

| Type of installation | Indoor |

| Maximum attitude | <1000m |

| Standards | IEC60076-11 |

Application and After-Sales Service:

Application and After-Sales Service:Application: Cast resin dry type transformer is widely applied to the power grid, solar power plant, wind power plant, hydropower plant, nuclear power plant, infrastructure, real estate, etc…

After-sales Service: We have a professional aftersales engineer team, each aftersales engineer has more than 3 years of experience. And we also have localized technical backup to offer timely support in Malaysia, South Africa, Egypt, Dubai, UAE, Brazil.

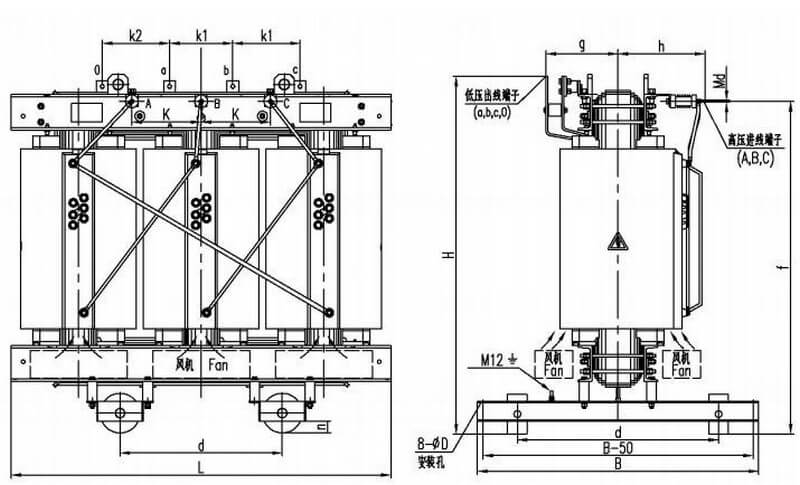

Core:

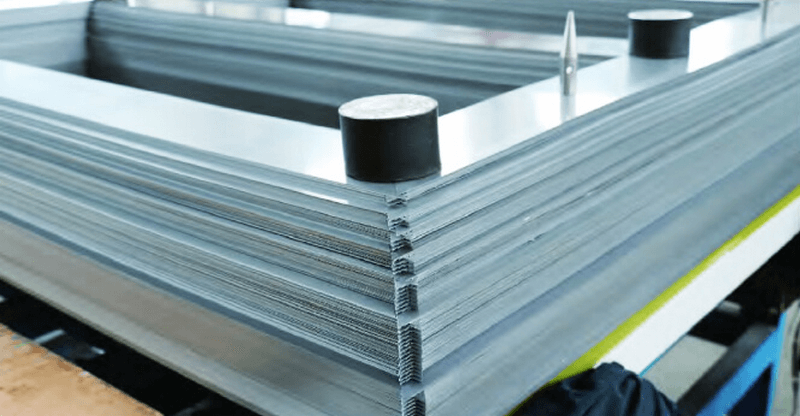

1. The core is made of high-quality grain-oriented cold-rolled silicon steel of high magnetic conductivity, by using the 45°five-step overlapping method to reduce the no-load loss and no-load current.

2. Simulation analysis method is applied for the core design, thus to precisely and effectively calculate the vibration frequency and scale.

3. Flexible connections are adopted between the core and coils, core and clamps. With these measures, the transformer’s noise level has been improved by 10-15dB over the conventional products.

Windings:

Windings:

Lv windings:

1. For LV windings above 400 kVA capacity, superior foil conductors are adopted for winding manufacturing, thus obtaining better amper-turn balance and less transverse magnetic flux leakage, and finally to greatly improves the transformer’s anti-short circuit capability.

2. By reasonably designing the oil passage within the winding, the winding’s heat dispersion effect is greatly increased. Thus the reasonable design has decreased temperature rise and improved products’ overload capability.

Hv windings:

1. HV windings are manufactured with superior wire conductors, insulated reinforced with fiberglass.

2. The HV windings are cast under vacuum and high-pressure conditions in Germany HUBER’S vacuum Cast Machine, resulting in the best resin penetration and very low partial discharge( partial discharge for 11kV product could be lower than 5Pc).

3. Optimized structure is adopted for HV windings to improve the transformer’s electric field. Lighting impulse simulation calculation was adopted for winding model design, thus substantially improve the product’s anti-lighting capability.

Cooling (AN/AF):

The transformer could be designed for AF (air forced) cooling or to be initially supplied for AN (natural cooling) cooling. Provisions shall be made for subsequent installation of or cooling which shall consist of 2 or more crossflow fans arranged on either side of the transformer below the windings.

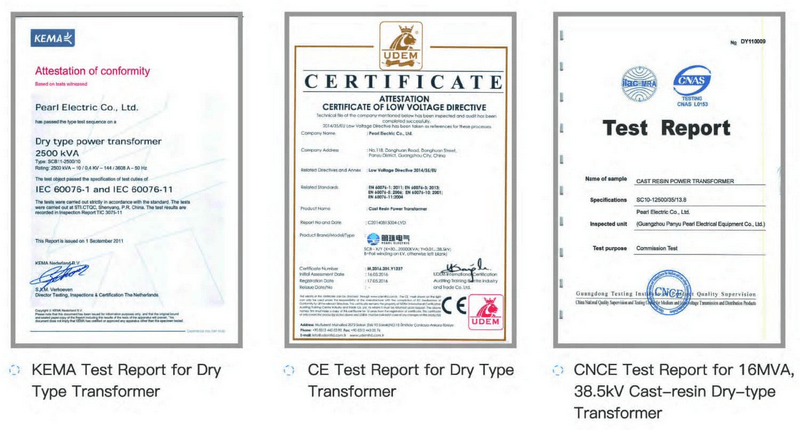

Test capability is an important part to show Pearl Electric’s high quality and R&D results. And each transformer must pass all tests before delivery.

1. Except short-circuit transformer, we can do all routine tests, type tests, and special tests for our transformer.

2. Having 4 test bays covered Dry-type transformer, oil-immersed power transformer, and transformer substation.

3. Getting a complete set of third-party test certificates for transformer, included KEMA, CESI, ASTA, CTQC, CNAS.

FAQ:

FAQ:1. Q: Are you a manufacturer?

A: Yes, we are a manufacturer. Our factory is in Guangzhou City, Guangdong Province.

2. Q: Can I get a guarantee of products?

A: Yes, every product is 12monts quality warrant under customer correct using the products.

3. Q: Do you have any Certificates?

A: Yes. Each of our unit has CE, 3C certificate and has awarded by ISO9001/ISO14001. If you need any other Certificate,

we can help you to apply it.

4. Q: How can I pay you?

A: Pay by T/T and L/C is acceptable.

5. Q: What about the production?

A: In general, it take 4~6weeks and it depend on the different style.

Copyright © Pearl Electric Co., Ltd.